What to Specify in a PCB Order

What you may need to specify when ordering PCB fabrication and assembly

Number of boards you need produced.

Desired turnaround time. The standard turnaround time is 4-5 days. Rush is 2-3 days. Very fast is same-day or 1 day turnaround. It’s not uncommon for a PCB manufacturer to ask for after hours contact information 1 day or less turnaround time.

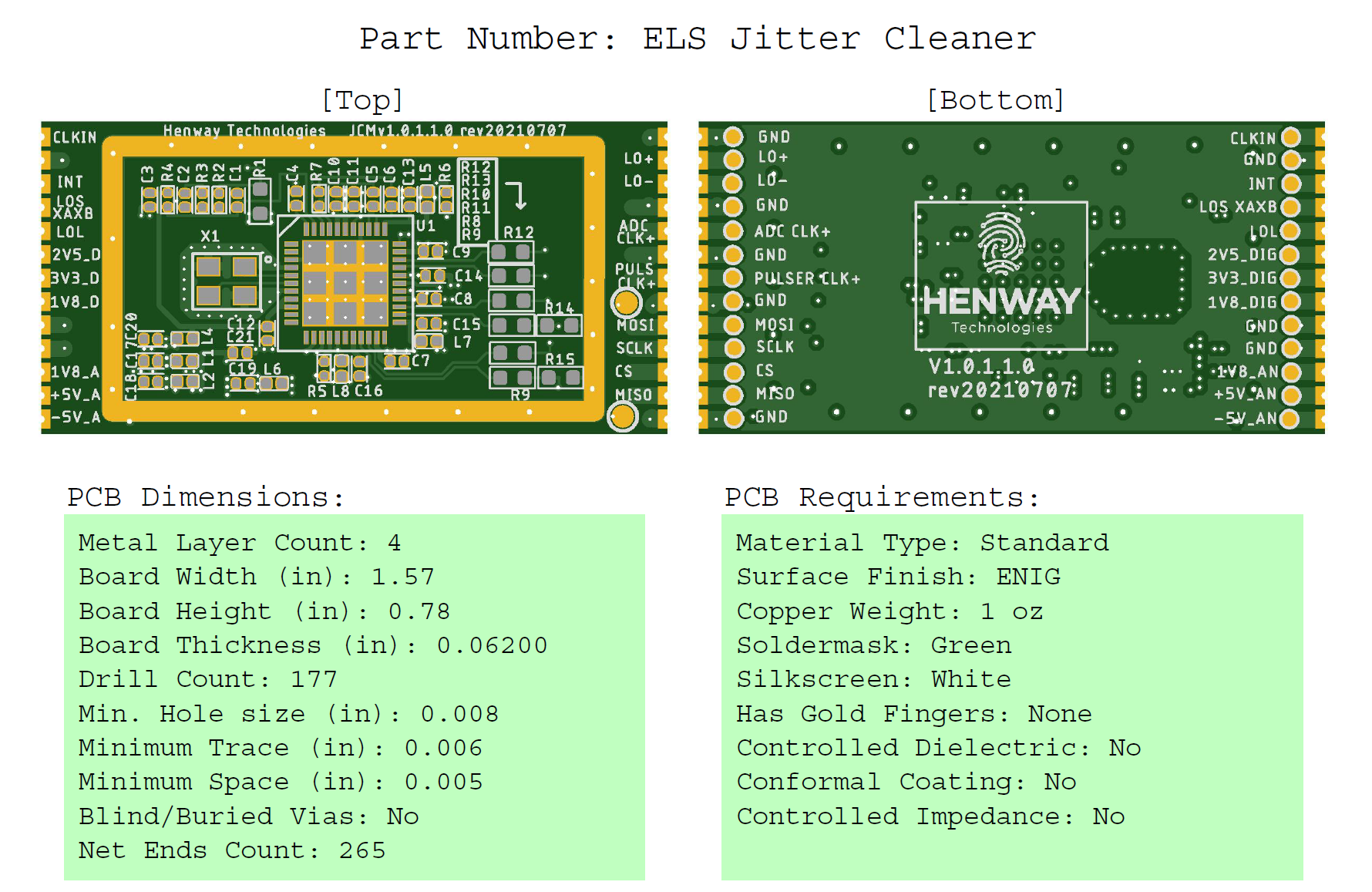

Total length and width of the PCB

The number of layers

Material (such as FR4, aluminum, Rogers, flex, rigid flex, etc). Standard may imply FR4

Total thickness . Standard may imply 0.062”

Min track/spacing. Standard implies 6mil trace/space. Advanced would be 2/2 or 3/3

Min hole size. Standard implies 0.008”

Soldermask color. Standard is green.

Silkscreen color. Standard is white.

Surface finish. Standard may be HASL or ENIG, ENIG being the better and more common of the two

Finish copper weight. Standard is 1oz on the outer layers, and 0.5oz or 1oz for the inner layers.

Leaded or lead free processing. The standard may vary depending on the facility

If there are any components that can’t go through a washing cycle such as delicate sensing elements, piezo speakers, etc. The designer must mention this in the order form or BOM

Specify if your design has any of the following additional features:

Half-cut/Castellated Holes Layers

Edge Plating Layers

Impedance control Layers

Halogen-Free Layers

Custom Stackup Layers

Carbon Mask Layers

Via in pad/ Via filled with resin Layers

Press-fit holes Layers

Countersinks/Counterbores Layers

Z-axis milling Layers

Files to provide

Gerber files

BOM in excel (we need the ability to format rows/columns and select text)

Assembly instructions such as how to solder cables to the board, how to mount the electromechanical components, clarify any ambiguities in mounting direction, etc)